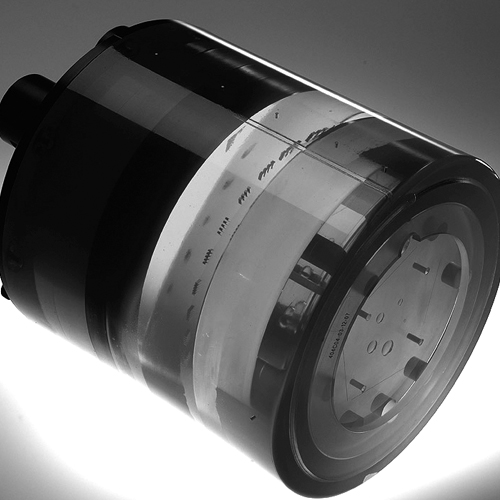

Catphan® 600

The Catphan® 600 builds on the capabilities of the Catphan® 500 model to enable maximum performance characterization of multi-slice CT’s and the enhanced sensitometry measurements required for radiation therapy. The Catphan® 600 has enhanced measurement capabilities for precise measurement of thin slices and higher resolutions found in multi-slice scanners.

Smári Image Analysis Service

The Catphan® 600 is equipped with Smári, a powerful, web-based image analysis service created by The Phantom Laboratory. Smári delivers automated phantom image analysis in the cloud and maintains measurements in a database for trend analysis, machine comparisons, and historical records.

For detailed phantom information please refer to the Catphan® 600 Datasheet and Product Guide.

Test-Summary

CTP404

- sensitometry (linearity)

- scan slice geometry (slice width and slice sensitivity profiles)

- pixel (matrix) size

- circular symmetry

- phantom position verification

- patient alignment system check

-scan incrementationCTP591

- slice width for thin slices

- slice width for thick slices

- MTF and SSP with two size point sources

- test on multiple slices in a multi-slice sequenceCTP528

- high resolution measurement -up to 21 line pairs per cmCTP515

- low contrast sensitivity

- comparative subslice and supra-slice low contrast sensitivityCTP486

- spatial uniformity

- noise (precision) of CT systems

Modules

The Catphan® 600 consists of 5 modules enclosed in a 20cm housing.

CTP404 Slice Geometry and Sensitometry Module: Opposed 23 degree wire ramps are used to measure scan slice geometry, verify phantom position and check the patient alignment system and the scanner table incrementation. The shallow 23 degree angle allows for more precise measurement of slice thickness than the commonly used 45 degree ramps and the thin wires allow for accurate measurement of thin 1 and 2mm slices without streaking artifacts. Gantry angle (up to 10 degrees) can be determined by the ratio of the ramp lengths.

The module includes 8 sensitometry targets (Teflon, Delrin, Acrylic, Polystyrene, LDPE, PMP, Air and a small vial for water) to measure CT number linearity. The increased number of targets makes this module suitable for radiotherapy CT sensitometry.

The module also contains five acrylic spheres to evaluate the scanner’s imaging of subslice spherical volumes. The diameters of the acrylic spheres are 2mm, 4mm, 6mm, 8mm, and 10mm.

Pixel size can be determined through measuring the number of pixels between the four holes (one with a teflon pin) located 50mm apart.

CTP591 Bead Geometry Module: The CTP591 module enables precise measurements of slice geometry of thin slices without artifacts sometimes seen with conventional ramps and high resolution measurements with an .18mm diameter tungsten carbide MTF bead or 50µ MTF wire.

The use of beads enables quick assessment and comparison of slice thickness in a multi-slice sequence verifying consistency across the detector area. The unique ramps are positioned in opposed pairs to eliminate errors caused by non-perpendicular alignment. There are 2 pairs of coarse ramps and 1 pair of precision ramps. The coarse ramps each contain 39 beads, traversing all but the last millimeter of the 40mm module. The precision .25mm ramps each contain 25 beads covering a 6mm range. For detailed MTF and SSP calculations, two isolated beads 0.28mm and .018 mm in diameter are located in the mid plane of the module.

For thin slice high resolution measurements, a 50μ diameter steel MTF wire runs through the full 40mm thickness of the module.

CTP528 High Resolution Module: This section has a 1 through 21 line pair per centimeter high resolution test gauge and two impulse sources (beads) which are cast into a uniform material. By minimizing the amount of high contrast material and employing a radial design, the CTP528 module eliminates streaking artifacts.

The spherical MTF beads can be used to obtain an accurate MTF curve characterization without tedious and time-consuming positioning inherent with MTF wires. The point source beads also eliminate the over-ranging problems and streaking artifacts that occur with MTF wires, because the bead density is volume averaged with the surrounding material.

CTP515 Low Contrast Module: The CTP515 consists of a series of cylindrical rods of various diameters and three contrast levels to measure low contrast performance. The 40mm-long rods provide consistent contrast values at all z-axis positions, thereby avoiding any volume-averaging errors as you scan through the section. The unique subslice test objects enable evaluation of the effectiveness of different scan protocols (pitch, slice width and reconstruction algorithms) in resolving subslice low contrast objects.

For selection of helical and multi-slice image protocols, unique subslice low contrast targets (truncated cylinders) have been included in this module. Comparing the images obtained by scanning the subslice targets with different imaging settings (slice width, pitch and reconstruction algorithms) provides valuable information to assist with the selection of optimal protocols for identifying small low contrast objects such as tumors.

All of the various samples and the background material have equivalent effective atomic numbers; only the density is varied to produce changes in the effective attenuation coefficients.

Subslice targets have a nominal 1.0% contrast and z-axis lengths of 3, 5, and 7mm. For each of these lengths, there are targets with diameters of 3, 5, 7 and 9mm.

CTP486 Uniformity Module: The image uniformity module is cast from a uniform material with a CT number designed to be within 2% (20H) of water’s density under standard scanning protocols. The typically recorded CT numbers range from 5H to 18H. This module is used for measurements of spatial uniformity, mean CT number and noise value.

Use of a solid material eliminates leaking or risk of damage from exposure to freezing temperatures. The CTP486 solid-image uniformity module provides consistent results, is much more convenient to use than modules using water-filled tanks, and eliminates variations due to different water sources. This solid material’s high radial and axial uniformity makes it an ideal substitute for water. It has been thoroughly tested over a wide variety of variables in the x, y and z planes and has proven stable in all applications.